BKG® BlueFlow™ Gear Pumps from Nordson Substantially Reduce Pressure Variation, Making Possible a Return on Investment in a Matter of Months.

MÜNSTER, GERMANY, March 28, 2019: Nordson Corporation has developed an online tool that quickly calculates the resin cost savings achievable with installation of a BKG® BlueFlow™ gear pump, plus the number of months in which the investment in the pump is paid back in full. The company will introduce the tool at Chinaplas 2019 (Booth 2.1F41).

Installed between the extruder and the die, a gear pump shifts the job of building melt pressure from the extruder to the gear pump. Besides reducing stress on the extruder and potentially increasing throughput, the gear pump significantly reduces the effect of process variations on melt pressure. This enables extrusion processors to run with narrower tolerances without compromising product uniformity.

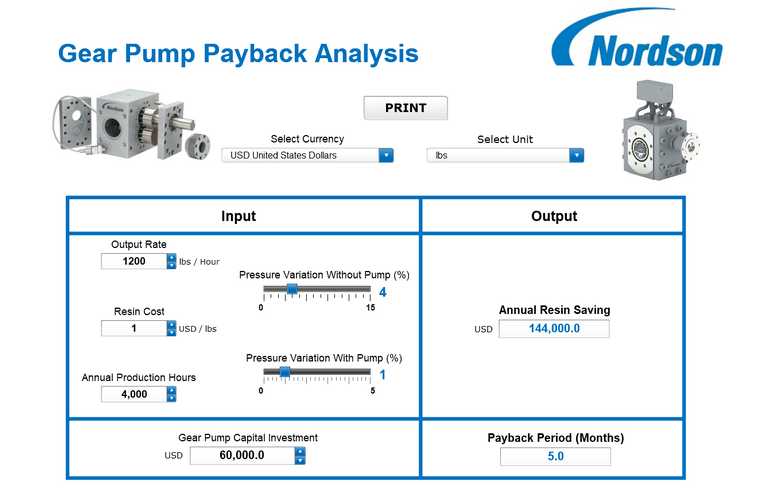

The new online tool, called the Gear Pump Payback Analysis, is posted at https://www.nordson.com/en/divisions/polymer-processing-systems/support/calculators. The tool calculates resin cost savings and investment payback time on the basis of resin price, output rate, pressure variation with and without the gear pump, and capital investment. These inputs can be made in either pounds or kilograms and in many of the world’s currencies.

“Even with a new screw, pressure variation without the use of a gear pump typically is in the +/- 5% range, making it necessary for the processor to use more resin in order to ensure that the finished product meets specification,” said Christian Schroeder, global product manager for melt delivery products. “By reducing pressure variation to as little as +/- 1%, the BlueFlow gear pump makes possible resin cost savings that can generate a full return on investment in a matter of months.”

forrás: nordson.com 2019.08.05

Nordsonpack videó