Gebr. Hoff en Zonen prepares fresh broccoli from own cultivation for delivery to supermarkets. In the packing hall in Andijk, a maximum of 140 broccoli per minute are shrink-wrapped in foil, weighed, labeled and sorted fully automatically. The labeling solution has been developed by cab and the local integrator Tegra Systems.

Until 2018, one conveyor line had been available to process broccoli. The new requirement was to add a second line to the plant and increase the output. André van Teeffelen, Sales Engineer at Tegra Systems, sums up: “The customer demanded solid technology that takes the work of the employees and operates quickly, precisely and error-free even in the longterm. The technology also collects all data that is of interest for the grower of the product, its customers in retail and wholesale, or the consumer. It contributes to the verification and traceability of broccoli as well as to food safety and quality”.

Custom labeling

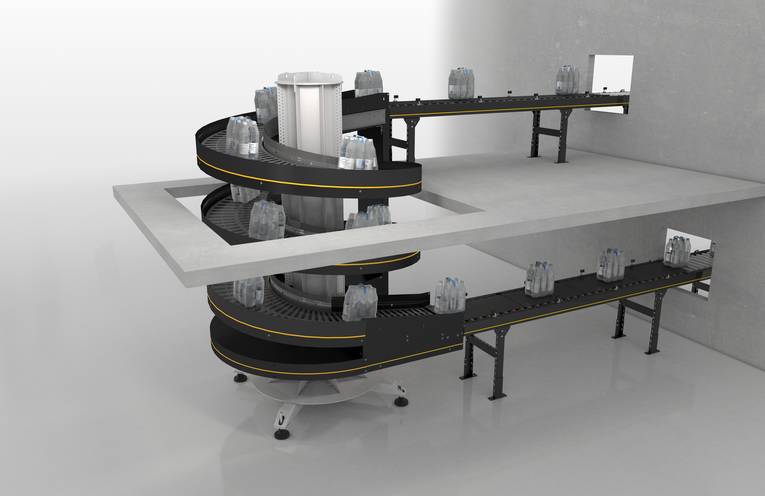

For Gebr. Hoff en Zonen, Tegra Systems put into practice an automated plant to shrink-wrap broccoli in foil, weigh, label and presort the vegetables after they had been poured in the conveyor line. Two Hermes+ systems are installed on each conveyor line for printing and applying labels. The first one is printing product information clearly legible on labels and applies them rapidly on each wrapped broccoli: What vegetable is it, what is its weight, which its commercial category? Which retailer will be delivered? Pre-printed decoration labels are applied by the second Hermes+. Finally, the broccoli arriving in rapid succession on the conveyor belt are sorted to the correct weight section.

Each broccoli differs. As a consequence, the printing systems have to apply labels dynamically on different sizes and shapes within a conveyor line. Further critical factors are the uneven surfaces of foils in use to shrink-wrap vegetables, and the quick succession at which broccoli pass the labeling stations one after the other.

Full labeling

“Hermes systems”, André van Teeffelen says, “can be very well integrated to conveyor lines with the help of stands, assembly aids, sensors or switches. The firmware enables fast printer programming. A minimum of efforts is required to maintain the devices. All this is exactly what we need in our plants”. cab for Hermes systems provides a large number of accessorial modules to apply printed labels on products – by tamping, rolling or blowing on labels, corner-wrap, on round materials such as cables or pipes. Any possible task can be solved. This versatility is unique on the market. In the case of Gebr. Hoff en Zonen, Tegra Systems decided for the air jet box 6114. Labels printed by the Hermes print unit are sucked by a fan. A powerful blast of air makes labels overcome distances of about 20 cm to apply on the broccoli without surface contact. No pressure is exerted on the vegetables.

About 200 kilometers away from Andijk, Pakstation Venlo sorts tomatoes, peppers, lemons and zucchini in nets or foiled packing. In the matter of labeling, two Hermes+ print and apply systems have been assembled in each packing line by the system integrator Zomerdam: one of the systems in classical manner, the other one upside down. By this, items in motion can be labeled from top and below. Pakstation Venlo aims in making 60 or 100 packings per minute instead of 30, if necessary. Thereby, labels have to be attached visibly and the information on the labels have to be clearly readable.

Company profile

cab is Europe’s leading manufacturer of devices and systems to label individual components, units, products and packaging. Healthy global growth, both technical and functional lead and competent customer support are prior goals of the company. There are 400 employees in Germany and in seven subsidiaries abroad as well as 820 distribution partners in more than 80 countries to meet the targets. For more information see www.cab.de/en

forrás: cab.de 2020.01.15