Shanghai, China –Liwayway, a leading snack food company, has placed an order to Interroll for a modular conveyor platform (MCP) system and three Pallet flow systems, which aim to upgrade its plant in Qingpu District, Shanghai.

Interroll’s new MCP system, which is about to be put into operation, will undertake the conveying of carton boxes from labeling, sealing and up to pre-stacking, with a throughput of up to 3,000 pcs/hr, thus completely breaking the bottleneck of Liwayway’s delivery issue.

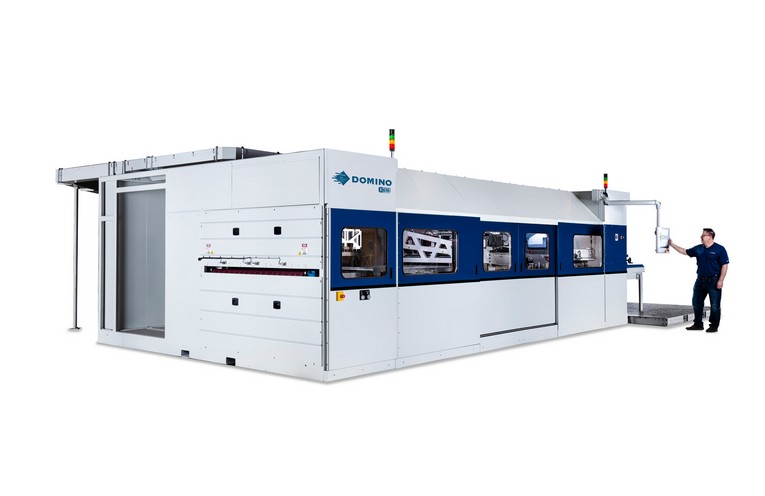

The main element of the new platform is a fully modular system that incorporates the variou

s key elements of conveying systems and can be assembled to form a complete material flow solution that renders the services needed. The modules include not only the straight sections and curves with and without drives; the portfolio also encompasses merge cassettes for loading and unloading goods, and alignment and belt conveyors for overcoming steep inclines, for example. Depending on the application requirements, the conveyor modules can be equipped with various drive systems and be combined with one another. Zero pressure accumulation conveyors can be realized by using the proven and extremely energy efficient 24 volt RollerDrive concept that operates without any pneumatic actuators. A 400 volt drive solution that has been optimized to handle high conveying speeds and extremely heavy goods (up to 50 kg) is also available for use in high-performance applications.

Moreover, the new MCP adheres to Interroll’s consistent open concept. All its modules can be seamlessly connected with the conveyor modules, greatly facilitating customers to upgrade and transform their existing systems. It is also the decisive reason for Liwayway to choose Interroll MCP because their own engineering team are able to design and change the delivery process according to the real and changing demands.

Liwayway has been a satisfied customer of Interroll Dynamic Storage Systems for many years already. Based on the layout of Liwayway’s Qingpu plant, Interroll will provide Liwayway with three pallet dynamic storage systems with a total of 2,160 pallet positions, including 960 positions FIFO storage system in the raw material warehouse and two LIFO dynamic storage systems with a total of 1,200 pallets positions, used in the two finished goods warehouses. The FIFO storage system uses Time-plus Safety Separators to ensure the controllable, uniform sliding of pallets and the highest safety of personnel. The LIFO dynamic storage system can make full use of the warehouse volume, greatly improving the storage density. Moreover, the system also uses Interroll’s new magnetic speed controller, greatly improving the safety and throughput of warehouse operations.

“We are grateful to Liwayway’s trust in us. Interroll couldn’t have made such great progress in China and in Asia without the trust and support of our customers. As a leading supplier of internal logistics, Interroll is committed to providing the Chinese market with better and more forward-looking products. We care not only about our customers’ today but also about their future,” said Dr. Ben Xia, Executive Vice President of Interroll Group, Head of Operations Asia. “The new modular conveyor platform is a very good example. The modular concept allows our customers to modify their conveyor systems at any time according to new market demands. Quick response to changing demands is the key to winning the future.”

“It has been a very successful experience to work with Interroll. Interroll’s FIFO dynamic storage system can not only ensure fast, energy-efficient inventory turnover, but also ensures that the first produced products are delivered first. This is extremely important in the food industry, and also the main reason why Liwayway chose Interroll.” commented Mr. Shi Xuezhi, Executive Vice Chairman of Liwayway (China) Co., Ltd. “Interroll is very innovative. The new modular conveyor platform is the most important product launch in the 57-year history of Interroll. Thanks to their support, our engineering team can successfully plan and design this conveyor system. We are looking forward to the MCP running and solving our pressing delivery issue eventually.”Interroll Profile

The Interroll Group is a worldwide leading producer of high-quality key products and services for internal logistics. The company offers a broad product range in the four product groups “rollers”, “drives”, “conveyors & sorters” and “pallet & carton flow” to around 23,000 customers (system integrators and OEMs) around the world. Core industries are courier, parcel and postal services, airports, food processing industry as well as distribution centers and other industries. Interroll products are in daily use at amongst others well-known global brands such as Amazon, Bosch, Coca-Cola, Coop, DHL, FedEx, Peugeot, PepsiCo, Procter & Gamble, Siemens, Walmart and Yamaha. Interroll is engaged in global research projects for logistics efficiency and actively supports industry associations in developing standards. Headquartered in Sant’Antonino, Switzerland, Interroll operates a worldwide network of 32 companies with around 2,000 employees. The company was founded in 1959. The Interroll Group has been listed on the SIX Swiss Exchange and included in the SPI index since 1997.

forrás:www.interroll.com

January 20, 2017 Sant Antonino, Switzerland